ASTM D4169, the standard practice for performance testing of shipping containers and systems, has recently been updated. The truck vibration data, profiles and testing techniques are the basis for the updates. Following is a summary of the rational for the update.

ASTM D4169, the standard practice for performance testing of shipping containers and systems, has recently been updated. The truck vibration data, profiles and testing techniques are the basis for the updates. Following is a summary of the rational for the update.

Rational for Update

In recent years the truck profile data referenced in ASTM D4169 Section 12.4 has not been representative of the data collected from recent truck measurement studies. As a result of this, the following updates have been made to reflect the more current field data that had been measured.

Three primary characteristics to any random vibration profile are as follows:

- Profile spectral shape

- Profile intensity (Grms)

- Profile duration (time)

1. Profile Spectral Shape:

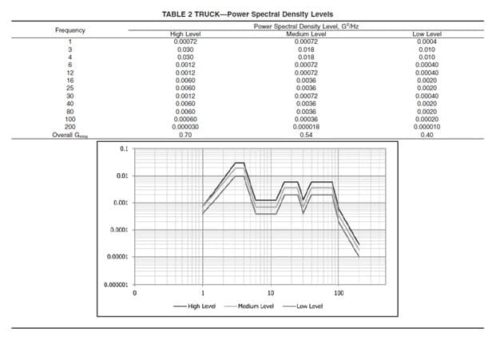

Based upon a number of recent truck measurements throughout the Americas, the spectral shapes measured match current and widely used industry test specifications. This provides justification to cross‐reference other widely accepted Steel Spring Truck profile as the basis for the proposed ASTM D4169 truck profile spectral shape.

2. Profile Intensity:

The current measured truck data comprehensive statistical data summaries show:

- 90% of the measured data is at or below an intensity of 0.40 Grms

- 95% of the measured data is at or below an intensity of 0.50 Grms

- 99% of the measured data is at or below an intensity of 0.73 Grms

The update recommends conducting the test using a consistent shaped profile at varying test intensities. The following paragraphs explain the proposed levels of intensity.

Low Level ‐

The measured data indicates that 90% truck vibration occurs at a lower intensity level of up to 0.40 Grms. The update to the D4169 Truck Profile recommends testing using the proposed spectral shape starting at an intensity level that is comparable to the 90th percentile of the referenced measured data.

Medium Level ‐

The current ASTM D4169 Truck Assurance Level II profile shape is not representative of the truck environment but its intensity level—0.52 Grms—is comparable to the 95th percentile intensity level of 0.50 Grms. The update recommends testing using the ISTA Steel Spring Truck Profile at the 0.54 Grms intensity level which is slightly higher than the 0.50 Grms level and can be considered a worst case medium intensity level vibration.

High Level ‐

The measured data also contains some vibration which occurs at a higher intensity (0.73 Grms). To simulate these more intense vibration events, the update recommends testing using the proposed spectral shape with an intensity level that is comparable to the 99th percentile of the referenced measured data.

3. Profile Duration:

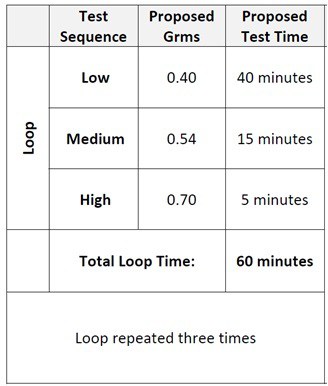

Currently, when performing an ASTM D4169 simulation for Distribution Cycles 1, 3, 4, 5, and 6, the truck vibration test is performed at a single intensity level (e.g. Assurance Level II) for the entire test duration. The update recommends the use of three different intensities—Low, Medium, and High—that correspond with the 90th, 95th, and 99th percentile intensities as discussed above.

The same measured vibration data used to determine the Low, Medium, and High intensity levels can also be analyzed to determine the relative amount of time that those intensity levels occur. By definition, 90th percentile (Low) intensity vibration occurs more often than the 95th percentile (Medium) intensity which occurs more often than the 99th percentile (High) intensity.

Many test labs have a historical precedent for using three‐hour test durations for ASTM D4169 vehicle vibration tests. The three‐hour test duration allows enough time for test items to respond to the test intensity and maintain an efficient time window from a test laboratory productivity perspective. To maintain that overall test duration of three hours (180 minutes), it is recommended that the truck profile spectral shapes are used at the following test intensities (levels) for a total amount of time as follows:

- Low Level: 120 minutes

- Medium Level: 45 minutes

- High Level: 15 minutes

Distribution Cycles 9, 10, 12, and 13 require simulating more than one type of vehicle vibration and only recommend a 60 minute Truck test. In other cases it may be necessary to rotate the test item so it experiences the vibration is different orientations. To accommodate all the different manners in which the Truck vibration will be utilized, the Low, Medium, and High test profiles should be performed in 60 minute loops as detailed below. For a 60 minute Truck test, only one loop would be performed. For a 180 minute Truck test, three loops would be performed.

Note: It is important to note that there have been no modifications to the air and rail profiles and they will continue to be executed as they have in the past.

Note: The rational provided with the ballot was used as a basis for this document.