ASTM F1929 “Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration” is a dye penetration package integrity test used by package engineers that is designed to detect and locate leaks caused by channels formed between a transparent film and a porous material.

The ASTM F1929 standard was first written in 1998, was reapproved in 2004, and then ASTM made a significant update to it in 2012. In 2015, the standard was updated with no significant changes. The standard was recently updated in December of 2023. The notable change in the newly revised standard is the allowed use of alternative surfactants other than Triton X-100 as the surfactant component in the dye solution.

DDL still receives many questions about ASTM F1929. Here is a quick overview of the changes over the years:

DDL still receives many questions about ASTM F1929. Here is a quick overview of the changes over the years:

ASTM F1929-98 (2004)

- Utilized injection method. Observe the package for any leaks originating from the inside edge of the package seal towards the outside edge of the package seal.

- Observe each seal for a recommended duration of 5 to 20 seconds.

ASTM F1929-12

- Three test methods are now called out:

- Test Method A: Injection method (same method used from previous ASTM F1929-98 (2004). Inject dye solution within the sealed package and observe for leaks, originating from the inside edge of the package seal towards/through the outside edge of the package seal.

- Test Method B: Edge dip method. Dip the outer edge of the package seal evenly within the dye solution and observe for leaks, originating from the ouside edge of the package seal towards/through the inside edge of the package seal.

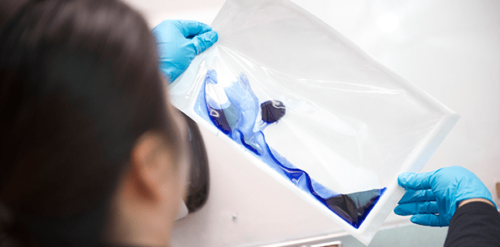

- Test Method C: Eyedropper method. Note: The Eyedropper method requires the packages to have an unsealed area that extends beyond the outer edge of the seal. Along the extended unsealed area (beyond outer seal edge), the transparent material is separated from the porous material (with use of a finger, paperclip, etc.). Most commonly, an eyedropper or pipette is used to apply the dye penetration solution between the transparent and porous materials of the unsealed area. Place a bead of solution between the two materials along the outer edge of the package seal, ensuring the entire outer edge of the seal is wetted with the dye solution. The package is then observed for leak,originating from the outside edge of the package seal towards/through the inside edge of the package seal.

- As a guide, each Test Method above recommends observing each seal for a maximum of 5 seconds on a 4-sided package (20 seconds total).

- If a channel is present in the seal, the location should be accentuated by the wicking of the porous substrate/material around the channel.

ASTM F1929-15

- No significant changes.

ASTM F1929-23

- The use of alternative surfactants other than Triton X-100 as the surfactant component in the dye solution is now allowed. These alternatives must adhere to the specified requirements:

- The surfactant should be nonionic.

- The chemical properties should align with a surface tension ranging from 30 mN/m to 33 mN/m, a hydrophilic/lipophilic balance (HLB) exceeding 10, and a critical micelle concentration (cmc) below 2000 ppm.

The ASTM F1929 is currently a recognized consensus standard by the FDA. Please keep this in mind when developing your studies and validations.

Please contact us with any questions you may have about ASTM F1929, or if we can help you with any other testing questions or projects.