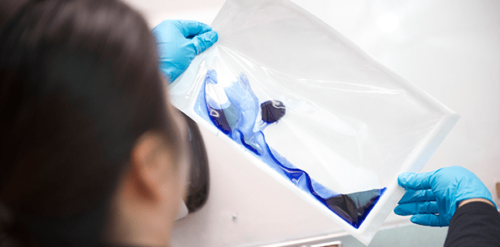

ASTM F88/88M, the standard test method for assessing the seal strength of flexible barrier materials was recently updated.

In previous revisions, Techniques A, B, and C in the standard offered clear testing instructions for flexible-to-flexible or semi-rigid packages (such as pouches), but it lacked clear guidance on conducting tests for trays made of flexible-to-rigid or semi-rigid materials.

The latest revision ASTM F88/F88M-23 has rectified this gap by providing users with guidance on conducting seal strength testing for trays. Two approaches relevant to trays have been incorporated into Technique C, offering users options to determine the most suitable method for testing their packages.

For further detail on this update, please see our recent video with DDL’s Lab Supervisor Kevin Rardon demonstrating Technique C performed on trays, along with Technique A and Technique C with pouches.

DDL has extensive experience conducting seal strength testing on trays. Historically, our approach involved following the flexible-to-intact rigid or semi-rigid structure method, and this approach will remain consistent in our future testing procedures.

Furthermore, we have carried out Test Method Validation (TMV) across all DDL locations based on this approach. This validation process further ensures the reliability and consistency of our testing method, providing added confidence in its repeatability and reproducibility.

In addition to the changes on the testing of trays, the new revision also provided updated information on:

- Flexible to flexible ILS background, rationale, and analysis in Appendix X1

- Flexible to Rigid ILS background, rational, and analysis in Appendix X2

- Impact of variation in sample width and separation speed in Appendix X3

- Optional test fixtures in Appendix X4

Please contact us for more information on Seal Strength testing or if you need help on an upcoming test.

DDL still receives many questions about ASTM F1929. Here is a quick overview of the changes over the years:

DDL still receives many questions about ASTM F1929. Here is a quick overview of the changes over the years: